Towing Protocol for Automatic 4x4s: Driveshaft Disconnection at the Differential Flange

Towing Protocol for Automatic 4x4s: Driveshaft Disconnection at the Differential Flange (Study of the Ford Ranger Wildtrak 2.0 with 10R80 Transmission)

I. Introduction: The Imperative of Drivetrain Isolation

The recovery of an immobilized 4x4 vehicle in complex terrain, such as mud fields or rocky slopes, goes beyond the simple application of pulling force. For the owner of a modern vehicle with an automatic transmission (AT), especially dual-use designs like the Ford Ranger Wildtrak 2.0, towing without proper precautions carries a catastrophic risk to the drivetrain.

1.1. Context: Why Off-Road Towing is Not a Standard Procedure

It is essential to differentiate towing categories. Emergency towing, as defined by the manufacturer, is usually a short-range, low-speed procedure. Off-road recovery long-distance towing, however, demand a distinct protocol.

The most frequent misconception among enthusiasts is assuming that the Neutral (N) position in the gearbox or transfer case offers total mechanical safety. While this may be sufficient to move the vehicle a few meters, it is not a substitute for mechanical isolation. Automatic systems depend on active lubrication, and any forced rotation of the drive axle in the absence of this hydraulic pressure must be considered negligence. The only way to guarantee the transmission´s integrity during prolonged or high-speed towing is through the physical disconnection of the prop shaft.

1.2. The Hidden Risk: Automatic Transmissions (AT) and the Deception of the Neutral Position

Unlike manual transmissions, which often use internal gear rotation (splash lubrication) to move oil and lubricate bearings, modern ATs operate under strict hydraulic pressure control. This pressure is generated by an oil pump to lubricate bearings, bushings, and cool the clutch packs.

The core thesis of any towing protocol is that the forced rotation of the transmission’s output shaft (connected to the driveshaft) when the engine is off causes immediate and severe wear. Internal components, rotating at road speed without the protective, coolant film of pressurized fluid, suffer overheating and metallic friction. Therefore, the experienced will always seek to completely isolate the source of rotational movement (the drive axle) from the transmission body.

II. Engineering Fundamentals: The Lubrication Dilemma in the 10R80 Transmission

The Ford Ranger Wildtrak 2.0 (European version) uses the Ford 10R80 automatic gearbox, a sophisticated ten-speed unit shared across multiple Ford and GM platforms. Understanding the lubrication mechanics of this unit is essential to justify the disconnection protocol.

2.1. 10R80 Architecture: Dual Pump Design

The 10R80 transmission, like many modern gearboxes, relies on a complex lubrication system that includes two main components:

The Main Pump (Mechanical): This pump, crucial for lubrication and hydraulic pressure management that applies the clutches, is driven directly by the engine, via the input shaft (connected to the torque converter). When the engine shuts off, this pump stops functioning, eliminating the necessary high-pressure flow.

The Auxiliary Pump (Electric): The 10R80 is equipped with an auxiliary electric pump, strategically located, often near the sump or at the rear of the housing, depending on the version. This component exists to maintain minimum fluid pressure during fuel-saving functions, such as "Start/Stop" systems at idle.

Engineering analysis shows that the auxiliary pump is not capable of sustaining the transmission during towing. Its design is geared towards low flow and pressure, sufficient only to keep the clutches ready for re-engagement after a brief engine stop. It is not sized or designed to provide the cooling or volumetric flow required to adequately lubricate the entire planetary gear train, support bearings, and bushings, which rotate at speeds equivalent to 80 km/h on the road. The dependence on the main mechanical pump, inactive when the engine is off, absolutely validates the need for physical disconnection of the drivetrain.

2.2. Hydraulic Lubrication Failure: Thermal Overload Analysis

The absence of adequate hydraulic pressure during forced towing generates friction. In the 10R80, points of vulnerability include:

Bushings and Bearings: The transmission output shaft, as it rotates, forces the internal components to turn. Without the fluid pressure acting as a hydrodynamic layer and heat dissipator, bushings and bearings suffer wear from metal-to-metal contact.

Clutch Packs: Even when clutches are disengaged, the lack of fluid circulation exacerbates residual heat. The 10R80 is already prone to specific failures like F-clutch wear or CDF drum sleeve slippage under normal stress conditions, problems that lubrication-induced overheating exponentially aggravates.

2.3. Manufacturer Limits: Interpreting Emergency Manuals

The Ford Ranger service manual sets a protocol for emergency flat-towing regardless of the drivetrain configuration, under extremely restrictive conditions:

* Maximum Speed: 56 km/h (35 mph).

* Maximum Distance: 80 km (50 mi).

This explicit limitation is not a suggestion but an engineering restriction. It indicates that the residual lubrication system (whether by splash or minimum flow from the electric pump if active) can only tolerate the friction and heat generated under these limited conditions.

If an off-road recovery operation requires towing the vehicle 150 km or at a speed exceeding 56 km/h, the manufacturer´s safety limit is being exceeded. This implies that any towing exceeding these parameters must be carried out with the drivetrain mechanically isolated, making driveshaft disconnection the only safe protocol for long-distance towing.

III. Strategic Disconnection: Differential vs. Transfer Case

The decision of where to disconnect the driveshaft (differential or transfer case) separates a safe operation from one that introduces mechanical and operational risks in the field.

3.1. Differentiated Roles: TC vs. Differential

It is vital to understand the functions of the components. The Transfer Case (TC) receives power from the transmission and distributes it between the front and rear axles in 4x4 or AWD systems. The Differential (Diff), in turn, manages the speed difference between the wheels on the same axle, facilitating turns. The goal of the disconnection is to interrupt the transmission line of wheel movement, isolating both the differential and the TC from that movement.

3.2. The Danger of the Slip Yoke on the Transfer Case

Historically, many 4x4 vehicles use a slip yoke design on the transfer case output shaft. This design allows the driveshaft to slide in and out of the case to compensate for suspension travel.

Disconnecting the driveshaft directly from a slip yoke-equipped transfer case presents two serious risks in the field:

Fluid Leakage: Sliding the yoke out of the transfer case breaks the dynamic seal, which can lead to rapid loss of fluid (ATF or TC oil), especially if the vehicle is on a slope. Loss of this fluid compromises TC lubrication.

Contamination: The exposed cavity becomes a potential entry point for sand, dust, mud, or water during towing, contaminating the TC’s internal lubricant.

3.3. Advantages of Intervention at the Differential Pinion Flange

The most effective and safest practice in the field is to release the driveshaft from the rear differential pinion flange, as most differentials use a bolted flange mount (Fixed Yoke/Flange).

The operational advantages are clear:

Clean and Safe Operation: Disconnection at the pinion flange is a simple mechanical operation involving the removal of the bolts securing the driveshaft. No dynamic seal is exposed, and there is no risk of fluid loss, as the pinion seal remains intact in the differential.

Total Isolation: This method ensures that both the automatic gearbox (10R80) and the transfer case remain completely immobile, reducing the risk of any rotational damage or contamination.

Accessibility: The rear differential is generally the most robust and accessible component for performing the maneuver under difficult recovery conditions.

IV. Critical Analysis of the Neutral Position (Neutral Tow Mode)

While the Ford Ranger offers an electronically controlled neutral tow mode, this system should not be considered a substitute for mechanical disconnection in a recovery environment.

4.1. Function and Electronic Activation Requirements of Neutral Tow

In vehicles equipped with an electronic transfer case, activating the four-wheel-down towing mode (Neutral Tow) requires a precise sequence. Generally, this involves having the ignition in the ACC or ON position (without starting the engine) and using the instrument panel to initiate the sequence, holding it until the vehicle confirms the message: NEUTRAL TOW ENABLED LEAVE IN N.

This mode internally activates a disengagement mechanism within the transfer case, separating the input from the output shaft, which theoretically stops the rotation of internal components.

4.2. Safety Limitations and European Context of the Wildtrak 2.0

The dependence on an electronic command is the weak point of the Neutral Tow mode in extreme situations:

Electrical Dependence: If the vehicle has suffered a severe electrical failure or a fault in the transfer case logic, the Neutral Tow system might be impossible to activate.

European Part-Time Configuration: It is crucial to highlight that the Ford Ranger Wildtrak 2.0 (European version, with part-time traction) is often not equipped with the electronic Neutral Tow mode. This feature is more commonly associated with permanent all-wheel-drive versions (Full-Time 4WD), such as more advanced V6 models.

Implication for the Protocol: The high probability that the Wildtrak 2.0 lacks this electronic mode elevates mechanical disconnection to a primary operational necessity. The only option to protect the 10R80 gearbox during long-distance towing is the physical disconnection of the driveshaft.

V. Field Protocol: Safe Rear Driveshaft Disconnection

The driveshaft disconnection procedure must be executed with precision to ensure safety during towing and prevent vibration issues upon reassembly.

5.1. Safety, Stabilization, and Essential Tools

Before any intervention, safety is paramount. The vehicle must be immobilized with the transmission in Park (P), the parking brake applied, and, if possible, with wheel chocks on the wheels opposite the working axle.

Essential tools include:

* Robust lifting equipment (bottle jack or Hi-Lift with base).

* Axle stands (jack stands).

* Socket and wrench set or open-end wrenches (generally 13 mm to 15 mm for flange bolts).

* Paint marker or punch for indexing.

* Torque wrench for reassembly.

* High-strength soft straps or wire to secure the driveshaft.

5.2. The Phasing Mark Procedure (Indexing): Ensuring Dynamic Balance

Before removing any bolts, the relative position between the driveshaft flange (where the U-joint is located) and the differential pinion flange must be marked.

The technical necessity of this step is critical: driveshaft assemblies are dynamically balanced at the factory. If the driveshaft is reinstalled out of phase, severe harmonic vibrations will be introduced, which will be felt at speed. At least two opposite reference points must be marked on the flange to ensure correct alignment during reinstallation.

5.3. Loosening, Removal, and Axle Handling

Proceed to loosen the four (or more) bolts securing the driveshaft to the differential flange. Progressive and uniform loosening is recommended. Once the bolts and retaining plates are removed, the driveshaft can be separated from the pinion flange. If the flange is very tight, a sharp blow with a rubber mallet or a small lever can help release it.

If the Ranger uses a two-piece driveshaft, only the rear section needs to be released and handled.

5.4. Securing and Fastening the Driveshaft

Once separated, the shaft must be carefully pivoted and secured firmly to the chassis or the vehicle frame rail. It is crucial to use high-strength soft straps or wires that will not cut or damage the chassis coating or the driveshaft itself.

A final manual check must be performed:

* Verify that the differential pinion flange rotates freely, confirming that the prop shaft is disconnected.

* Verify that the secured driveshaft does not rub against the exhaust, brake lines, ABS sensors, or any other moving component during towing.

VI. Extended Protocol: Towing in Engaged 4x4 Mode (4H, 4L, 4A)

The riskiest scenario in recovery is when the vehicle stops with the transfer case (TC) engaged in 4x4 mode (4H, 4L, or 4A, if applicable). In this situation, the movement of both axles will rotate the internal components of the transfer case and, by extension, the 10R80 transmission output shaft.

6.1. The Need for Double Isolation

If the transfer case is stuck or locked in a 4x4 mode and cannot shift to 2H or Neutral (N), the rotation of the front and rear wheels will transmit movement to the TC. Therefore, the protocol requires the disconnection of the driveshaft at the differential on both axles.

Rear Axle (Mandatory): Disconnecting the rear driveshaft is essential to protect the automatic gearbox output shaft (10R80) and the rear part of the transfer case, where rotation can be severe.

Front Axle (Conditional): Disconnecting the front driveshaft is necessary to isolate the drivetrain from the forced rotation of the front differential, thus protecting the transfer case´s internal mechanism.

6.2. Procedure on the Front Axle

The front axle disconnection procedure is identical to the rear:

* Safety: Stabilize and secure the vehicle.

* Marking (Indexing): Mark the phase between the driveshaft and the front differential pinion flange to ensure future alignment.

* Removal: Remove the bolts securing the driveshaft to the flange.

* Securing: Pivot the front driveshaft and secure it firmly to the chassis, ensuring it does not rub against the suspension or the Electric Power Assisted Steering (EPAS) system.

Critical Note: In the Ford Ranger, the front differential may have an automatic disconnection system (IWE - Integrated Wheel End). Although this system should disengage the wheel axle when in 2H or if the TC is in Neutral, the only way to guarantee absolute isolation when the TC is stuck in 4x4 is the physical disconnection of the driveshaft.

VII. Critical Vehicle Aspects: Ford Ranger Wildtrak 2.0 (10R80)

7.1. Rear Axle and Component Identification

The Ford Ranger Wildtrak 2.0 (Next-Gen or T6, depending on the specific year in Europe) generally uses a robust rear axle. The driveshaft mounting to the differential is usually via a bolted flange to the U-joint, simplifying disconnection.

7.2. Torque Specifications for Reassembly

Reassembly should not be performed without a torque wrench. The torque specification is critical. An incorrect tightening (excessive or insufficient) can lead to bolt failure, loosening due to vibration, or damage to the pinion flange.

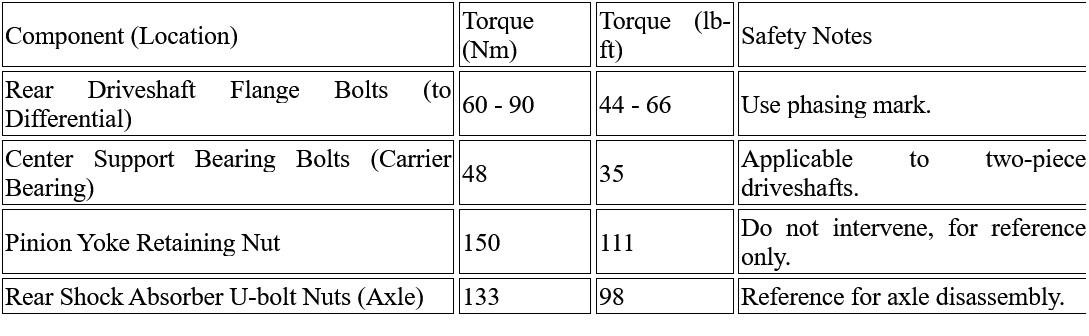

For execution, the following reference tightening torques should be used for reassembly and other drivetrain components on the Ford Ranger:

The pinion yoke retaining nut, with a torque of 150 Nm, is significantly higher than the flange bolts, underscoring that disconnection must be performed at the flange (60–90 Nm) and not by attempting to disassemble the entire pinion.

VIII. Electric Power Assisted Steering (EPAS) and Column Lock

A frequent challenge in towing modern vehicles with total failure is managing the Electric Power Assisted Steering (EPAS), which the Ranger Wildtrak 2.0 utilizes.

8.1. EPAS System Operation without Electrical Power

The EPAS system requires electrical power to operate the motor that provides steering assistance. When the battery is drained or the electrical system is inactive, assistance disappears. Although the steering wheel can be turned, the resistance is extremely high, making precise maneuvering difficult or impossible, especially if the vehicle is wedged.

8.2. The Danger of the Anti-Theft Lock

The main risk is not just the lack of assistance, but the activation of the anti-theft steering column lock. This is a physical mechanism activated when the ignition is turned off or the key is removed. If the vehicle runs out of battery and the lock is active, the steering wheel becomes completely immobile.

Towing a vehicle with the steering locked, even if only to maneuver it onto a tow platform, is extremely dangerous and guarantees major damage, not only to the steering system but to suspension components and potentially the bodywork.

8.3. Critical Solution: Use of a Booster or Auxiliary Battery (12V)

EPAS management in a modern rescue makes the towing procedure an electromechanical act.

The field protocol requires the rescue operator to have a 12V booster or an auxiliary battery. By connecting power, the ignition must be turned to the ACC or ON position (without starting the engine). This simple step energizes the ignition circuit, releasing the steering column lock and allowing the steering wheel to turn freely (albeit without assistance).

It should be strictly avoided to drag the vehicle without releasing the lock or attempting to turn the steering wheel by applying excessive force without assistance, as this could damage the electric rack torque sensors, resulting in a very expensive repair. The ability to temporarily restore steering is an essential requirement for safe towing.

IX. Conclusions and Recommendations

Off-road recovery of a Ford Ranger Wildtrak 2.0 with a 10R80 automatic transmission demands a higher technical rigor than suggested by short-distance emergency towing protocols.

The engineering evidence regarding the 10R80 transmission´s dependence on the engine-driven hydraulic pump, and the inability of the auxiliary electric pump to compensate for this deficiency during towing, establishes that drivetrain isolation is mandatory for the unit´s safety.

Driveshaft disconnection at the differential pinion flange is confirmed as the safest method. It overcomes the operational deficiencies of working on the transfer case (risk of leakage and contamination from the slip yoke) and, given the probable absence of the Neutral Tow Mode in the European 2.0 versions, it becomes the only measure of total mechanical safety.

Final Recommendations for the Operator:

Total Mechanical Isolation: Always disconnect the rear driveshaft from the differential for any towing exceeding manufacturer limits (56 km/h or 80 km).

Double Disconnection in Stuck 4x4: If the vehicle is stuck with the transfer case locked in 4x4 mode (4H, 4L, 4A), it is essential to disconnect the driveshafts from both axles (front and rear).

Phasing Protocol: Rigorously mark the driveshaft position on the differential flange to ensure dynamic balance upon reassembly, preventing future vibrations.

EPAS Electrical Management: Always ensure an auxiliary 12V power supply (booster) to release the steering column lock and allow vehicle maneuverability during towing or loading.

Torque Use: Reinstall driveshaft and center bearing bolts with a torque wrench and apply the correct tightening torques (60–90 Nm for flange bolts).

X. Protocol Generalization: Applicability to Other 4x4 Platforms (Hilux, Land Cruiser, Bronco)

The towing protocol derived from the Ford 10R80 transmission architecture is, in essence, a universal engineering principle applicable to the vast majority of modern 4x4 vehicles and pickups with conventional automatic gearboxes.

10.1. The Universal Principle of Automatic Transmission

The golden rule for automatic transmission (AT) protection—that lubrication depends on the flow of the engine-driven main pump—is applicable to virtually all torque converter ATs on the market, including:

Toyota Hilux (and Fortuner): They use automatic transmissions (often Aisin-derived, like the AC60 or newer variants) that operate under the same hydraulic principle. Towing the Hilux with the engine off without driveshaft disconnection would result in severe damage to the gearbox gears and bearings. Disconnection at the rear differential is the standard practice in the field.

Toyota Land Cruiser Prado (250 Series): Despite its greater sophistication and likely use of a high-performance automatic gearbox coupled to a Full-Time 4WD system (which does require a Neutral mode in its transfer case), the risk of electronic or lubrication failure is identical. Driveshaft disconnection provides the necessary physical isolation that electronic systems (like Neutral mode) cannot 100% guarantee.

Ford Bronco: The Bronco (excluding the Sport model) uses transmissions from the 10R family (10R60 or 10R80/10R100) and shares the same drivetrain logic with the Ranger and F-150. Therefore, the disconnection protocol to protect the gearbox is an identical and absolute requirement.

10.2. Protocol Applicability Criteria

To determine if this protocol is applicable to any other vehicle (old or new), two key criteria must be evaluated:

Transmission Type: If the vehicle uses a torque converter automatic transmission and does not have an auxiliary pump sized for road-speed lubrication flow (which is almost universal), disconnection is necessary for long-distance or high-speed towing.

Disconnection Point: If the transfer case uses a slip yoke, disconnection should always be performed at the differential pinion flange to prevent leaks and transfer fluid contamination. If the vehicle is towed while engaged in 4x4, driveshaft disconnect must be double (front and rear) on any platform to protect the transfer case.

In conclusion, this protocol is the base 4x4 rescue methodology for protecting modern automatic drivetrains. Adopting it ensures the mechanical safety of the vehicle’s most vulnerable and expensive component.